Nail making machines have revolutionized the production of nails, making the process faster, more efficient, and highly precise. These machines are designed to transform raw materials like steel wire into finished nails of various shapes, sizes, and types. The process begins with feeding the wire into the machine, which cuts it to the desired length. Following this, the machine forms the head and points of the nail with remarkable accuracy. Modern nail making machines are equipped with advanced features like automated feeding systems, adjustable settings for nail dimensions, and mechanisms to ensure minimal wastage of material.

The benefits of using nail making machines are numerous. They offer unmatched speed compared to manual production, with some machines capable of producing thousands of nails per minute. This high-speed production is particularly advantageous for industries requiring bulk supplies of nails, such as construction and furniture manufacturing. Additionally, these machines are highly versatile, enabling the production of specialized nails like roofing nails, concrete nails, and decorative nails, all tailored to meet specific industry requirements.

Advancements in technology have led to the development of energy-efficient models, further reducing operational costs. Furthermore, automated systems minimize human intervention, significantly lowering the risk of errors and improving product consistency. For businesses, investing in a high-quality nail making machine translates to enhanced productivity, reduced labor costs, and higher profit margins.

Nail Production Machine

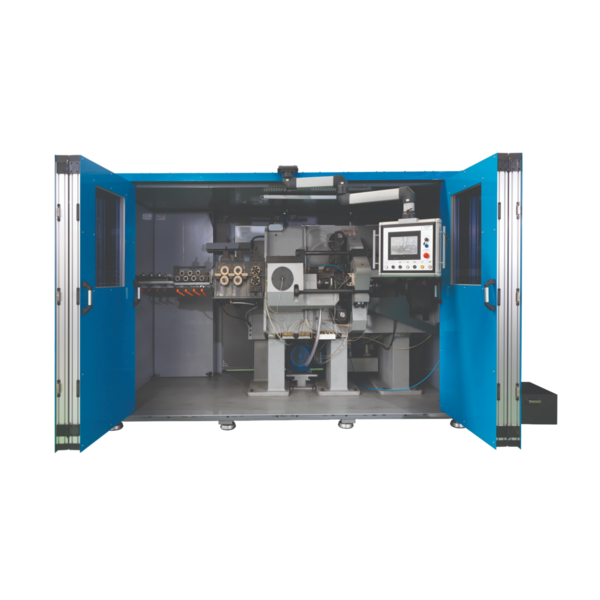

The term “nail production machine” is often used interchangeably with nail making machines, though it generally refers to a broader category that includes additional processes beyond nail formation. Nail production machines are designed to handle the entire lifecycle of nail creation, from wire feeding and cutting to polishing and packaging. This comprehensive approach ensures that manufacturers can streamline their production lines, saving both time and resources.

One of the key features of nail production machines is their ability to integrate multiple processes into a single system. For example, some machines include polishing drums that smooth the nails after production, eliminating sharp edges and enhancing their visual appeal. Others come with in-built quality control mechanisms, such as sensors that detect and reject defective nails. These features not only improve efficiency but also ensure that the final product meets stringent quality standards.

The versatility of nail production machines makes them suitable for a wide range of applications. Whether you need standard nails for construction or specialized nails for artistic projects, these machines can adapt to your needs. Moreover, modern models are designed with user-friendly interfaces, making them accessible even to operators with minimal technical expertise. By automating complex processes, nail production machines empower manufacturers to scale up operations while maintaining consistent quality.

Nail Manufacturing Machine

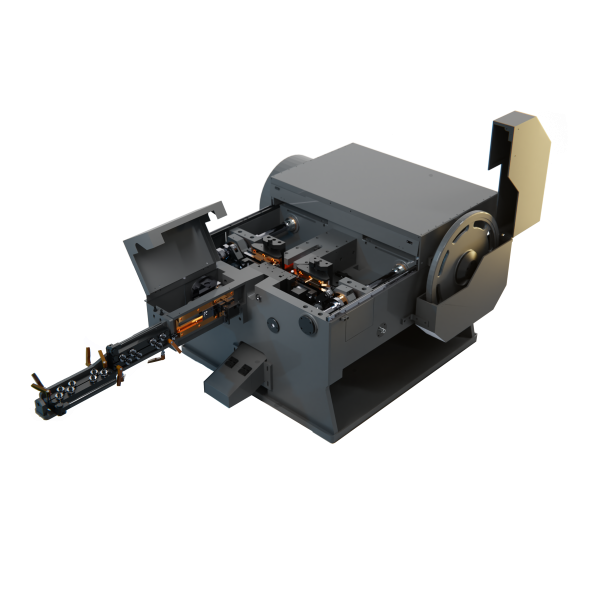

Nail manufacturing machines represent the pinnacle of industrial innovation, designed for large-scale production with unparalleled precision and efficiency. These machines are engineered to meet the demands of high-output environments, offering robust performance and durability. Unlike basic nail making machines, manufacturing machines often include advanced functionalities like multi-wire feeding systems, automated sorting, and real-time monitoring.

The manufacturing process typically involves several steps. First, raw wire is straightened and cut to the required length. The machine then shapes the nail’s head and point, ensuring a uniform finish. Advanced models also feature heat treatment options, which enhance the strength and durability of the nails. This is particularly important for nails used in heavy-duty applications, such as concrete or masonry nails.

A significant advantage of nail manufacturing machines is their adaptability to diverse materials. Whether working with steel, brass, or aluminum, these machines can handle a variety of inputs, providing manufacturers with greater flexibility. Additionally, their modular designs allow for easy upgrades, ensuring that businesses can keep pace with evolving industry trends. With a focus on sustainability, many modern machines are designed to minimize energy consumption and material waste, aligning with global efforts toward eco-friendly manufacturing practices.

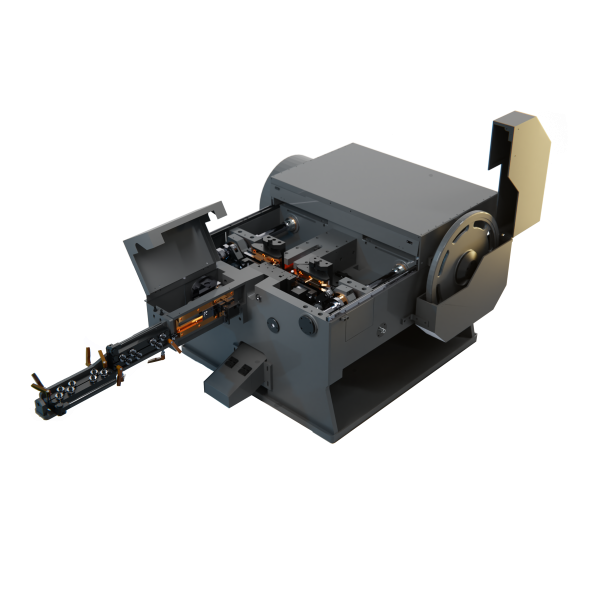

Thread Rollers

Thread rollers are indispensable tools in the nail production industry, used to add threads or grooves to nails, screws, and bolts. These machines enhance the functionality of nails by improving their grip and performance in specific applications. Thread rolling is a cold-forming process where the nail shank is pressed between hardened steel dies, creating a uniform and precise thread pattern. This process not only strengthens the nail but also ensures consistent quality.

Modern thread rollers are designed for high-speed operation, capable of processing thousands of nails per hour. They are equipped with adjustable settings, allowing manufacturers to customize thread dimensions based on specific requirements. Advanced models also include automated feeding systems and real-time monitoring to ensure seamless operation. The precision offered by thread rollers is unmatched, making them essential for producing nails used in specialized applications like roofing, flooring, and decking.

One of the key benefits of thread rollers is their ability to enhance the mechanical properties of nails. The cold-forming process improves material strength, ensuring that nails can withstand higher levels of stress and load. Furthermore, the versatility of these machines enables manufacturers to produce a wide range of threaded products, catering to diverse industry needs.

Conclusion

Nail making machines, nail production machines, nail manufacturing machines, and thread rollers each play a vital role in modern nail production. Together, they form an integrated ecosystem that ensures efficiency, precision, and versatility in manufacturing. Whether you are looking to produce standard nails or specialized threaded products, investing in high-quality machinery is the key to staying competitive in the industry. For cutting-edge solutions and state-of-the-art machines, visit Zeus Techno today. Explore their extensive range of products and discover how they can transform your production processes.